SR20 Strip Down - Part 2

Sunday, 18 October 2009 | Comments (0) | Categories: Engine

Yesterday I completed the tear down on the SR so it could be sent off to Heinz for the bottom end rebuild once the replacement parts arrive. The task though was to remove the crank, rods and pistons so all I was left with was a block.

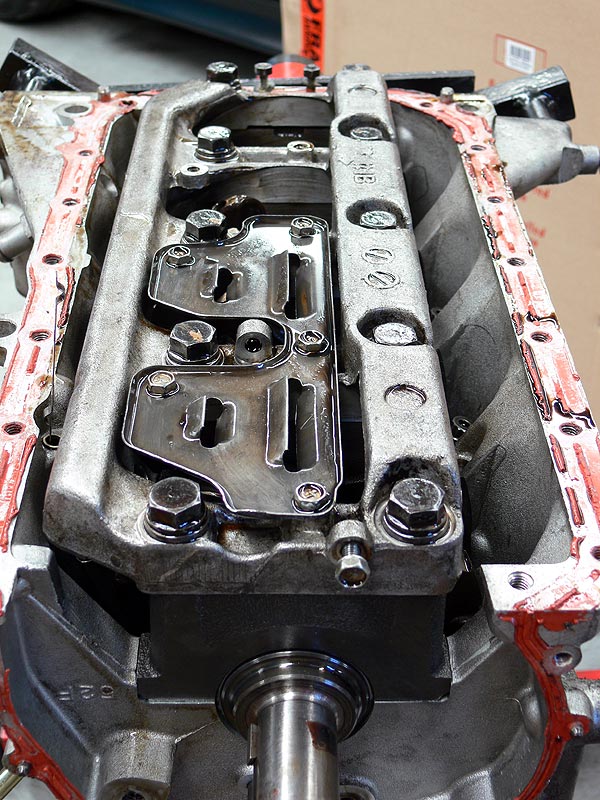

- SR20 Crank girdle and oil baffles

- SR20 GTi-R Oil Pump removed

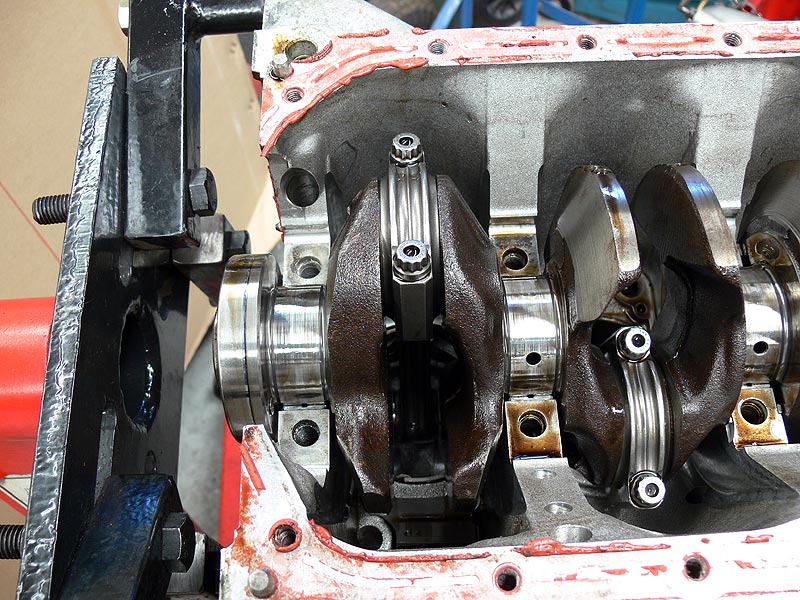

Once the oil pump was gone, the girdle could be removed and then the main caps for a good view of the journals and bearings. These are Eagle Forged Conrods with ARP rod bolts. The journals seem to be on OK condition and should just require a polish.

- Piston 3 Conrod caps

- Piston 2 Conrod caps

- Piston 1 Conrod caps

- Main bearings - show some heavy usage

- Close up of the bore

- Close up of the crank journals

- Rod and pistons now removed

- Eagle Rod with Z32 piston

After this was all done, it was time to put the shopping list together. I made the decision to no longer use the GTi-R oil pump as after a bit of research it was hit and miss on the whether or not the oil leakages can be stopped. It will be replaced with a standard S13 pump and we'll get the gears cryo treated for some extra insurance. With the reversion back to the standard pump, the GFB light weight pulley will no longer fit properly. This means with another GFB pulley, a standard SR20 dampened pulley or another aftermarket one. I'd heard nothing by good things about the Ross Harmonic Balancers, and although a 4-cylinder doesn't really need it, it's just good to use them anyway. So that will be on the shopping list.

Of course the Tomei metal head gasket can't be reused without a few hours work so a new one will be ordered. Now the big question comes around pistons...what to get. The original intention with the engine was response over all out power, and after good results from other engines C-Red had built with higher compression pistons, the decision to order a set of CP Forged Pistons with a 9.0:1 compression ratio has been made.

If you remember back to the track day, I was a little surprised to see oil up on the intake side of the engine and my thoughts are that the sandwich plate for the GReddy Oil Cooler kit is a potential fail point in the system. It uses only a single screw in the centre to latch onto the original mounting for an oil filter. I'd been eyeing off an item from Tomei call the N2 Oil Block which basically replaces the standard factory oil block with one that takes -10 AN lines instead of a filter...tick! The last obvious item is a replace releave pivot in the form of a Nismo Reinforced Release Pivot.

So now it's a matter of waiting for the parts to come in and then send off for bottom end rebuild. I thinking that will put us fair and square in the Xmas shutdown period so I am expecting some delays. Not to mention I know I have too much work on too.

Cheers

Brendan