Monday, 13 August 2007 | | Categories: Engine, Exterior, Suspension

Well it's been a couple of weeks since Autosalon, and during that period it was a time of rest and spending some quality time with the family. Many thanks to all the kind words that I've received...they're coming from all over the place including the US and Europe. But now it's back to situation normal...meaning only about 3hrs a week to work on the car.

So first up last week it was time for the tailshaft (driveshaft) to be installed. Now one thing to keep in mind here, is there hasn't been a tailshaft on this car for close the 3 years, meaning all brackets and bolts are long gone. If you're going to take on any restoration project, got get yourself a very large quantity of plastic snap-lock bags, a permanent marker and a bunch of plastic boxes to store the little bits in. Why? Because when it comes time to bolt things back up, it can take considerable amount of time to find the correct nuts, bolts and/or washers. This time I spent close to 50 minutes finding and then cleaning the tailshaft and centre bracket bolts. Once I had them, it was a fairly simple task.

Then I looked at the rest of the exhaust system. See for the show, I only had the rear section hanging by the rubbers so visually it looked complete. Now it was time for the front pipe, centre section and sometime this week the cat converter. The front pipe is the section between the turbo dump pipe (or Turbo extension as HKS calls it) and the catalytic converter. In my case I have an HKS Dump Pipe and HKS Front Pipe, both of which have been ceramic heat coated. So off I went to get some gaskets and flanges for the cat and dump. Now the 3-bolt gasket I got from Finnex didn't quite fit correctly, so I used the die-grinder to extend the bolt holes. (Note to self, put gasket into vice or you'll ruin the gasket!). After ruining the first gasket (plus wasting more time going and getting another), I had all the bits I thought I needed - and now ran out of time.

So now this weekend just past, it was time to focus on the front pipe. A quick test fit unfortunately revealed that it was going to be hitting the underside of the car. We can only speculate that because we now have nice new Nismo mounts, it was raised the engine up enough to cause the interference. No matter, we used an additional 3-bolt flange as a spacer (plus an additional gasket of course) to drop the front pipe down enough to clear. Yay, it fitted. Then the centre section of the exhaust was put on. Fairly simple affair, but damn that exhaust sealant can get bloody everywhere! With the addition of the mounting point that attaches to the rear subframe bolted up, the exhaust is looking good.

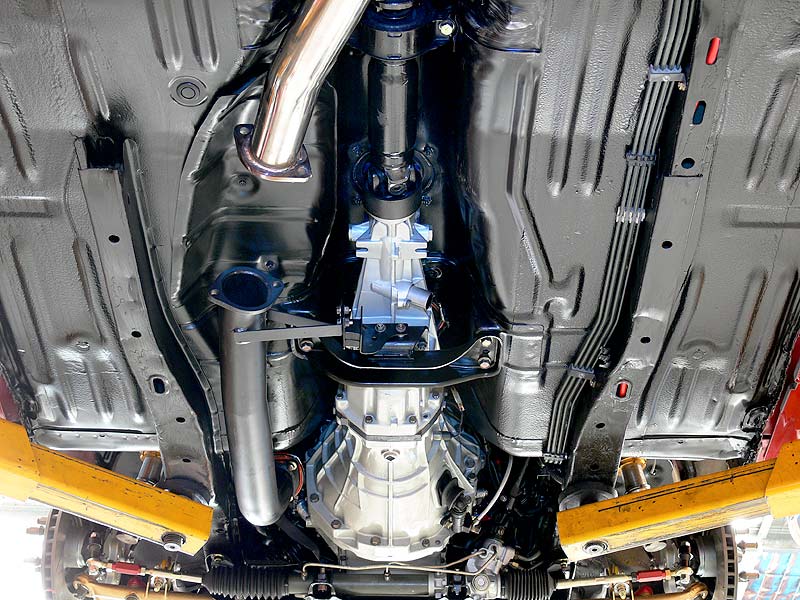

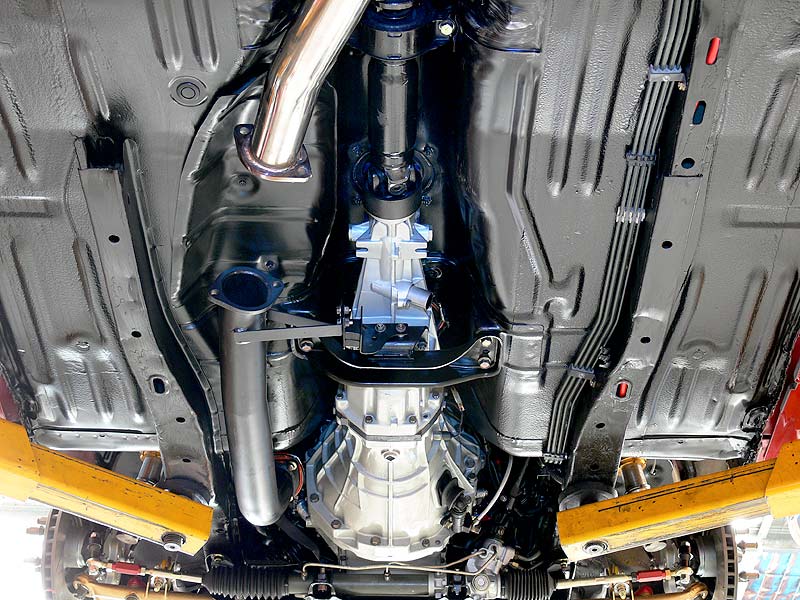

While on the hoist, I removed the wheels in preparation for the brakes to be bled and the cat converter and all the flanges and gaskets are in a single box ready to go on. Not having many pics of the underside, I setup the camera on the tripod and took a few snaps. Here's the results:

- Under the engine from rear

- Under the engine from front/side

- Under the engine from front

- Front Suspension assembly from front

- Front Suspension assembly from rear

- Rear Subframe assembly from rear

- Diff closeup

- Rear suspension assembley

So with these bits done, and the brakes and clutch being filled and bled at some point this week, attention will turn to getting the engine turning over. After that, it'll a matter of getting all the pieces left over sorted so it can be put over the pits. This includes things like the lights, indicators, washer bottle, oil catch can and as well as having an engineer take a look.

I'm so itching to get this on the road...my old Sigma is really showing signs of old age (which after doing 310,000kms is not surprising).

Cheers

Brendan

Thursday, 26 July 2007 | | Categories: Exterior, General, Shows

Photo Gallery

Here's a few photos I took while waiting for the truck to come and take sillbeer off to Autosalon last Friday night. They're a bit rough, but it shows the potential for some nice pics in the future.

If anyone is wanting a larger, desktop/wallpaper sized photo for their machine, let me know and I'll post a small selection up in a few different sizes.

Enjoy

Brendan

Monday, 23 July 2007 | | Categories: General, Shows

Photo Gallery

Phew, I'm glad that's over. Yep...referring to the hectic lead up to Perth Autosalon 2007 that I had last week. The target was to get the car pretty much 100% completed, but we had to settle for about 85%. Visually it was complete, but due to the short amount of time left over we didn't manage to turn the engine over and troubleshoot in time so we left it at that.

The week started out with a list, and by Friday afternoon I think I'd managed to cross off about 50% of the items...some big, some small. I was just happy enough to get it looking like it should, even if only the rear exhaust section was just hanging on the rubbers. But during this week, I did have the help of some top technicians in the form of C-Red's Marc, Josh and resident welding gnome. Even though they were busy with the three other C-Red cars, they managed to find time to point me in the right direction when needed...I can only say thank you all so much.

Once we had the cars into the convention centre, it was time for me to pay attention to the bodywork on SILLBEER. I had cleaned up everything else before going on the truck, but left the paint until I was in situ. Thanks again go to 200SXY from Silvia...you're tops. Not having had to really worry about show quality paint before, she kindly lent me her Meguires products and microfibre clothes to initially clean the paint work (which was filthy from sitting in a workshop for 2yrs) and then on Saturday morning, the wax to finish the job. I was completely surprised by how much of a difference these two products made. There's still a few blemishes on the paintwork, but with a proper buff and detail I reckon we can turn it up a few notches more.

The weekend was great in all and I came away with an award for 'Best Overall Engineering' which I was surprised at considering the car wasn't even running. But I suppose they saw the quality of parts and work that was put in by all and sundry.

Am I happy with the result so far? You betcha. The comfiness of the interior is what has most surprised me. The use of the R34 GT-R seats was spot on, and the softer materials used in the trimming and carpets has transformed an interior that I remember as being quite dated, cold and hard to something that you don't mind spending time in. Of course the quality sounds coming from the thumping stereo help.

So to end this post, I'd like to thank a few people. First and foremost would be my wife and three kids for supporting my efforts thus far with the car...you patience has been worthy of your own trophy. I've already thanked the boys at C-Red, but additional thanks go to Jeff Ash, the MD for C-Red...cheers buddy.To Roy Robinson - now heading up Kensei for his work and support in the earlier stages of the project (larv ewe). To Greg Dally for sitting in during the early parts of this year and knocking a lot of work off the list. To Pete and Chris at Trimcare for doing an awesome job on the interior trim work and carpets. Daniel Jurkovic from Audio Addict for his immaculate work with the stereo install. Phil Foster from A.F.M. Enterprises for helping out with some final painting bits (he also painted the C RED S14 with 1JZ). SilviaWA members for continuous support and kind words. And last but not least...myself, cause it was hard work.

Where to from here you might ask? Engine will be first off the rank followed by a run-in tune. Then we'll be getting the help of an engineer to see what we need to get done to have it all registered. Then some kms to run everything in and shakedown support systems. And somewhere in there a decent alignment and tweaks to the suspension to get a baseline to work from with regard to tuning the chassis.

...the journey continues...

Cheers

Brendan

Friday, 20 July 2007 | | Categories: General, Shows

A quick one.

Well this last week has been nuts trying to get ready for Autosalon this weekend. The kit and stereo are in, but there's been many many small things to do. Made a list at the beginning of the week, and I'm only half way through it so a few things will need to be missed unfortunately just to get it to the show in a worthy state.

So the next time I see you I hope to have heaps of photos to show you from the show.

Cheers

Brendan

Monday, 9 July 2007 | | Categories: Interior, Driveline, Suspension

Jeez, the pressure is really on now to get the car done. And now I'm taking a holiday! Last week was a little hectic with a lot of little things to do. Of the main things, the interior is all in (just need to bolt in the glove box once the loom's been tied away), the fuel system is finished, the mirrors are being painted and the carpets are done. The main battery line has been secured in its final resting place, the stereo installer is all set to do his magic (Daniel Jurkovic - 0408 792 466), and Tomas is scheduled to come in later in the week to refit the body kit.

So, how does the trim work look...in two words - bloody fantastical. Pete, Chris and the guys at Trimcare have done a great job, in minimal time and fuss...if you need any trim work done, please don't hesitate to go see them (Trimcare - Unit 3, 233 Bank Street, Welshpool - 9470 3381).

With the floor mats, they used originals as a template for the main shape and had the edges bound. For the specB badge, we mounted in the factory position, but as it wasn't as solid as the original, and the carpet is rather plush, they had to melt the fibres under the badge so it didn't bow in the middle once riveted into place.

- S13 specB Floormats

- S13 specB Floormats (closeup)

- Boot Carpet (centre)

- Boot Carpet (drivers side)

- Boot Carpet (passenger side)

The door trims came up a treat - ignore the whitish tinge, it's chalk marks that I'm yet to clean off. The plastic trims and centre console were all sprayed back to the original black colour, and the gearboot and handbrake cover are now in place. You can also see that the centre console box lid is trimmed in the same material as the back seat, door trims and glovebox.

- Centre Console

- Dash all fitted

- Air-conditioning Controls

I tell you I had a rabbit of a time with the air-con control. Firstly the head unit I had hadn't been cleaned once in its lifetime and it took me 30mins of rubbing hard with the prepsol to get down to the shiny plastic again. Once it was all clean, it was time to fight the octopus which was the wiring. I had to go track down a fuse, and missing solenoid for the airbox - along with a bunch of running around to different cars trying to figure out what went where. I also found one of the Nissan console DIN-sized storage boxes too (woohoo).

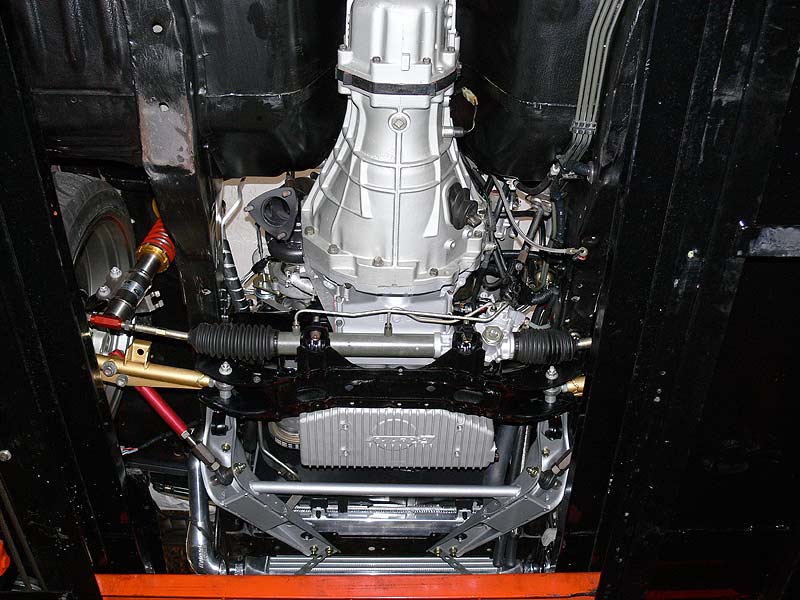

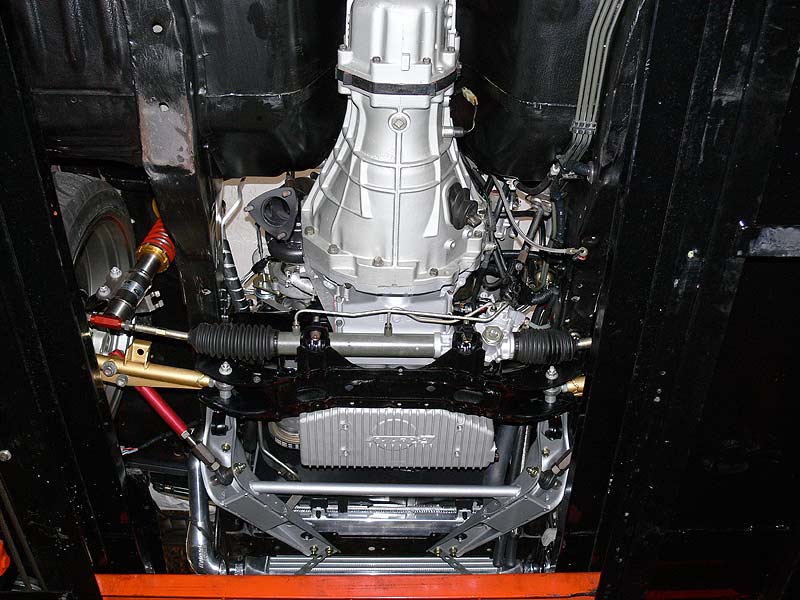

Doing all this work took place on the hoist, so while it was in the elevated position, I took a few pics of the underside for all those that haven't see it yet. Note you may see some flaking red paint in bits which is actually the hoist, not the car.

- Back of gearbox/tunnel

- Diff from the front (R33 GT-R Diff and Half-shafts)

- Diff from the back

- Rear Wheel suspension etc from the back

- Rear Wheel suspension etc from the front

- Front Wheel suspension etc from the back

Taking the weekend off as we've had a place booked down south for quite a number of months now, then next week I'm focussing only on the car to have it ready for Autosalon. Hopefully I can get one more post in before the show.

Cheers

Brendan

Wednesday, 4 July 2007 | | Categories: Interior

A few weeks ago I decided to take the logo application to the next level and commissioned a company call Badge-a-Minit to turn it into a plaque/emblem/badge thingy. The price was reasonable too for a custom one off piece of work. The process goes like this, the take the artwork I created (a vector file format called EPS), digitise it into a bitmap that their engraving machine can read which turns it back into vector artwork. The engraving then happens on the aluminium material - in this case branded Gravoxal. Once the engraving is done, the areas are paint filled and finally the top surface is linished back for a clean final product.

I had two different sizes made up, the larger ones will go on the new floor mats being made (fixed using rivets), and the smaller ones are yet to find a home, I think one will go on the dash somewhere, the other possibly in the engine bay. I still need to apply a final coat of clear for their protection and then they'll be ready for fitting.

I'm pretty happy really.

Cheers

Brendan

Wednesday, 4 July 2007 | | Categories: Exterior, Interior

Last Friday was a big day for me. It was the day the windows were being installed...finally changing sillbeer from a shell, to a car. But before they were done, I had to do some final prep. The interior needed to be removed for one, and the last bit of Dynamat was applied to the rear parcel shelf. While the rear glass was still out, I also drilled some holes for a future harness bar that we'll mount across the parcel shelf because once the glass is fitted, the area will be too tight for a drill.

- Dynamat on rear parcel shelf

Now once the windows were fitted by the kind fellows from Wayne's Windscreens, I took some pictures to remember the moment...you can tell now it's completely changed the outlook of the car.

- Windows installed from rear

- Windows installed from above

- Windows installed from above rear

While that was all going on the last of the interior pieces were gathered together and taken down to Trimcare to be refinished. You can see from the pics that some of the pieces were painted in a marble effect paint...this just isn't my bag, so it'll be brought back to stock.

- Centre console with marble effect paint

- Interior pieces for refinishing

Now as much as I wanted to on Saturday, I had to wait the obligatory 24hrs for the window sealant to cure so I've split my weekday in the workshop this week and spent the Monday PM refitting the interior (well what I had of it anyway). This included the newly trimmed rear seats and front door panels.

- Rear Seats now in place

I even sat in the back and belted myself in to see how comfy it is. I must say the logo really works well. I also went down to Clark Rubber and picked up some nice trim for the holes over the rear strut towers where the brace comes through. The final product looks great, noting also the plastic trim now looks new.

- Rear Strut Tower trimmed and ready to go

Now one thing that I've been trying to solve is the problem with the Nardi boss kit just not covering up the hole in the steering column surround. I did a bit of research and the only ones that seemed to be what I needed were from Nismo. After chasing that up and finding out they're discontinued, I turned to the Yahoo Auctions...and found quite a few of the correct design. Now whether they're genuine Nismo or not is yet to be determined, but I bid on two of them and won both so hopefully they'll be sent over asap. Oh, and I used Slidewise Imports to do all the dirty work, thanks Zac. Here's some pics of the boss kits I won:

- Nismo 'Style' Boss Kit for S13 - 1B

- Nismo 'Style' Boss Kit for S13 - 1C

- Nismo 'Style' Boss Kit for S13 - 2

And finally on Monday I got my Ganador mirrors. Bought from someone on NS.com, they're in great condition and have been dropped off to Phil at AFM Enterprises Osborne Park to be resprayed in the correct colour:

- Ganador Mirros from Front

- Ganador Mirrors from Top

- Ganador Mirrors sail

- Ganador Mirrors plug

Only three weeks or so now until Autosalon so the race is really on to get the car completed. Yet to do are bodykit fit, fuel system completion, catch can, stereo and battery along with a myriad of small bits and pieces.

Wish me luck, going to need all of it.

Cheers

Brendan

Tuesday, 3 July 2007 | | Categories: Interior

Well as I'm now using the R34 GT-R seats now, I sort of sold the Recaro's to a close friend. Unfortunately he's needing to sell them now for his own reasons. If anyone is interested (probably more people from West Coast and than east due to possible shipping costs involved), please email Clint on clinton 'at' cceg.com.au to find out more.

Cheers

BrendanI

UPDATE: They're sold.

Thursday, 28 June 2007 | | Categories: Audio, Interior, Suspension

Didn't the logo come up tops! I'm extremely happy with the way the logo has come out...not to mention the trim so far. The trim is currently in the very capable hands of Chris, Peter and the team over at Trimcare in Welshpool. The rear seats have been trimmed, the vinyl on the door trim has been repaired, and the time the photos were taken, they were still to be resprayed back to factory original colour.

- Door trim insert logo

- Door trim inserts ready for fitting

- S13 Rear Seatback trimmed ready to go

While Trimcare have been working on the cloth trim pieces, I worked on the boot - specifically the rear Cusco Strut Brace and the additional OST brace. Essentially you fit the main brace and centre the bits, then fit the triangulating braces that reach to a plate on the floor. You mark the holes on the floor, drill a nice clean guide hole using a small drill bit, then proceed to drill the main hole. Then get on your back, riggle under the back of the car (mmm, looks so clean under there), and pit the backing plate into position which is just above the differential. I also fitted up the Zenith Boot Brace which ties the ends of the chassis rails together in a similar way to the standard S15 rear boot brace does.

- Holes drilled in boot floor for bottom plate

- Zenith Rear Boot Brace

Of course all these bits will need to come out again, but finding all the bits and making sure it all fits is all part of the process.

Now the plastic trim in the boot usually covers up the top of the suspension towers, so once you fit a rear strut tower brace, it no longer fits. So the solution is to cut holes in the plastic trim so the brace and come through as well as giving enough room to adjust the coilovers damping. With this in mind, and the use of an engraving/dremel tool I set about cutting holes on an already busted set of trims. Using a tape measure and pencil I roughed out a guide to cut. I fitted a 20mm cutting wheel to the dremel and made my first cutouts, cleaning up the corners with a small 8mm diameter grinding stone. Test fitting revealed that the holes could be made smaller, so with that I measured out on the good trims and an hour or so later it was done. These boot trims were also dropped over to Trimcare so that can be refinished in the factory colour. The edges of the holes will get a clean rubber trim put around the edge.

- Suspension tower trim hole (passenger side)

- Suspension tower trim hole (driver's side)

You can see though that the original colour of the car (ie. white) is showing through the holes, so I masked up the area and used some Wurth's Matt Black paint to darken the area. Once the trims go back on, it should look need and tidy.

- Suspension tower painted (passenger side)

- Suspension tower painted (driver's side)

As the paint can was out, I quickly masked up the rear tow loop that sticks out under the rear bar and painted that too. It was looking rather scummy, but I sanded it back and found a cleaner black plastic trim and now it's up to spec. Oh, and considering I was tinkering at the back, I refitted the number plate lights that I had cleaned up. This also involved taking the old tape off the wiring which runs inside the boot and re-wrapping in new tape. With new bulbs in place and a bit of grunting trying to plug them back in (as the plugs are up on top of the steel bumper), all went in without a problem.

- Tow Loop (top)

- Tow Loop (bottom)

- Number plate lights re-fitted

Meanwhile Marc has been completing the wiring loom, the Splitfire coils are in place, the injectors are wired up and there's hardly a wire to be seen thanks to the Marc Palmer Special Service (you really need to look for them). Oh, and all that stereo gear was picked up thanks to Alex at Westside Car Audio in Osborne Park. I got a great deal on the gear, including the DDLinear Flagships. The amps are tiny and much lighter than an older 1000w monoblock is, so it evens out the use of all the dynamat  Now I might have to upgrade my iPod because I need a later version...but that's a tax deduction anyway.

Now I might have to upgrade my iPod because I need a later version...but that's a tax deduction anyway.

Seeya round

Brendan

PS> Apologies for the later than normal posting date.

Tuesday, 19 June 2007 | | Categories: Audio, Engine, Interior

Hooray...the last of the dynamat (except rear parcel shelf..dammit) is in the boot (trunk). After I ran out a couple of weeks, it took a few days to order, then more to deliver etc. But Friday I focussed on completing it...meaning the drivers side boot floor, suspension tower, outside guards and rear panel around the lights.

- Dynamat on the boot driver's side

- Dynamat on the boot rear panel

Once that was done, I went and tracked down some rear boot carpet and floor mats. After a good vacuum and clean, the floor mats just didn't seem to be coming up any good. The floor carpet was a little better. I'm going to get the floor mats remade now with a nice plush carpet. There's also a possibility of getting some badges made up for the mats based on the logo I designed, but still waiting back on quotes for them.

Next was to sort out the fuel pump. Now my original plan was to use a Sard single pump surge tank, but due to time restraints, we're just going with an in-tank pump that we'll use in the surge tank later. The pump chosen is the Bosch 044, but in an in-tank installation. The modification and fitting to the standard fuel cage was reasonably straightforward thanks to some instructions from NissanSilvia.com and help from the C-Red team.

- Fuel pump access prior to the dynamat

- Original S13 fuel pump setup

- Bosch 0 580 254 044 (The 044) Fuel Pump

- The 040 vs 044 fuel pumps - swapped over fittings

- Bottom of the bracket removed

- Fuel feed pipe shortened

- Fuel feed pipe attached to 044

- Completed 044 fuel pump assembly

- Completed Pump Install now with dynamat

In addition to these main things, I installed the electric aerial and went and got new (ie. used) license plate holders as mine seemed to have caught the attention of the spray painter's gun.

- License Plate light covered in overspray

- License Plate light in great condition

I'm due to get the seats back from the trimmers sometime later this week so I'll be throwing those in on Friday. Greg was helping out on Saturday too, working on getting the fuel system complete involving the Sard fuel pressure regulator (FPR), fuel filter and fuel lines to the rail and back. Oh, and I got some new pedals too from Natetune on NissanSilvia.com, aren't the purdy.

- Nardi Foot Pedals

Until next week.

Cheers

Brendan

PS> Sorry for the title, was still thinking of all those 'THIS IS SPARTA!' funnies that are running around at the moment (see the movie '300').